PCQI 2.0 Training & Certificate — FSPCA Approved

Become a Preventive Controls Qualified Individual (PCQI) with a fully online, self-paced course built on the latest Food Safety Preventive Controls Alliance (FSPCA) 2.0 curriculum. You’ll earn your official FSPCA certificate and gain the skills and confidence to develop and manage FDA-compliant food safety plans under the Food Safety Modernization Act (FSMA).

Great self-paced course with tons of knowledge to absorb. It provides great explanation on preventive controls and how to develop a proper and extensive hazard control (mitigation) plan. Overall, great course that teaches you a lot and allows you to complete it at your own pace!

Overview

Whether you’re advancing your own career or training your entire team, Registrar Corp’s PCQI 2.0 Training gives you everything needed to create and launch a strong food safety plan — on your schedule. Unlike many PCQI trainings that simply explain the regulations, Registrar Corp helps you put FDA compliance into practice. You’ll gain ready-to-use food safety plan templates, real-world examples, and step-by-step guidance from our FSPCA Lead Instructor with over 25 years of global food safety experience.

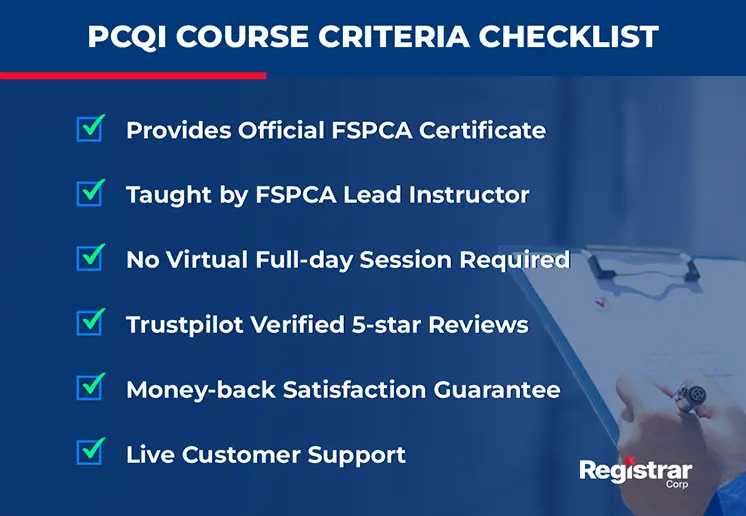

Before you sign up for a PCQI course, make sure it meets these must-have requirements, which is why more than 11,000 FSQA professionals have earned their PCQI certificate through Registrar Corp.

Registrar Corp’s PCQI Training is the fastest path to becoming a PCQI. Registrar’s 100% online course does not require an additional virtual full-day session afterwards, which could take weeks or months to schedule.

Get started today to:

- Master the latest FSPCA 2.0 curriculum to meet FDA PCQI requirements.

- Train on your time, at your pace with a fully online course, no scheduling required.

- Download your FSPCA Participant Manual and Exercise Workbooks.

- Access templates to build a solid food safety plan.

- Learn from an FSPCA Lead Instructor with global food safety expertise.

- Take advantage of group discounts & progress tracking for your food safety team.

- Rely on Registrar Corp’s live customer support and 100% satisfaction guarantee.

Registrar Corp brings more than 20 years of compliance expertise to give you the best, most streamlined path to PCQI 2.0 certification.

Curriculum

What You’ll Learn in the PCQI 2.0 Course

This PCQI 2.0 course covers every topic outlined in the official FSPCA 2.0 Preventive Controls for Human Food curriculum throughout 16 chapters that cover:

- A Food Safety Plan Overview

- Current Good Manufacturing Practices (cGMPs) and Prerequisite Programs

- Biological, Chemical, Physical, and Economically Motivated Hazards

- Developing and Conducting a Hazard Analysis

- Identifying and Implementing Preventive Controls

- Process, Allergen, Sanitation, and Supply Chain Preventive Controls

- Verification, Validation, and Recordkeeping Procedures

- Recall Planning and Implementation

- FSMA Regulatory Framework and Responsibilities

You’ll learn the regulatory expectations and how to build a working food safety plan as part of your coursework — a valuable reference you can apply immediately in your operations.

FAQ

What is PCQI 2.0 training and certification?

The PCQI 2.0 course is the updated version of the standardized curriculum for Preventive Controls for Human Food (PCHF), developed by the Food Safety Preventive Controls Alliance (FSPCA) and recognized by the U.S. Food and Drug Administration (FDA). It is designed to train and certify a Preventive Controls Qualified Individual (PCQI) at a facility, as required by the Food Safety Modernization Act (FSMA).

Who should take the PCQI 2.0 course?

If your facility is registered under Section 415 of the Federal Food, Drug, and Cosmetic Act and manufactures, processes, packs, or holds human food for consumption in the U.S. (or exports to the U.S.), the FSMA requires you to have a trained Preventive Controls Qualified Individual (PCQI) to develop and manage a compliant Food Safety Plan.

This training is ideal for:

- Food safety professionals responsible for developing or managing food safety plans

- Production, quality assurance, and compliance managers that support legal compliance and risk management

(Note: If your facility works with animal food, you should take the PCQI for Animal Food course.)

Why earn your PCQI certification?

Earning your PCQI certificate ensures your facility meets FDA requirements and protects your business from fines, recalls, and shutdowns. PCQI training teaches you to prevent hazards, create recall-ready plans, and minimize the financial impact of food safety issues. It also strengthens operations with FDA-recognized best practices, simplifies audits, builds a strong safety culture, and ensures supplier compliance.

Beyond compliance, your PCQI certificate equips you to confidently lead food safety initiatives across your facility, and also helps advance your career.

Why should I Take Registrar Corp’s PCQI 2.0 Training?

Registrar Corp’s PCQI 2.0 Training offers a flexible, practical way to meet FDA and FSPCA requirements — all online and at your own pace.

Registrar’s 100% online PCQI course does not require a follow-up full-day session with a virtual instructor prior to earning your certificate. These sessions required by other courses are scheduled once a month, so it could be weeks or even months before you can get enrolled, thus delaying your certificate.

Built on the official FSPCA 2.0 curriculum, Registrar’s FDA-recognized course helps you turn compliance into action with real-world examples, downloadable templates, and expert instruction from an FSPCA lead instructor.

Rated 5 stars by professionals worldwide, Registrar Corp combines regulatory expertise with modern online learning to help you earn your official FSPCA certificate and strengthen your facility’s food safety compliance.

Team training is easy too, with group enrollment options, volume discounts, and progress tracking for multi-facility programs.

Is this PCQI 2.0 training recognized by the FDA, and will I become a PCQI after completing it?

Yes. Registrar Corp’s PCQI training follows the FDA-recognized curriculum developed by the Food Safety Preventive Controls Alliance (FSPCA). By successfully completing the course, you’ll earn your official FSPCA PCQI certificate and become qualified to meet FDA requirements for Preventive Controls, ensuring your facility’s food safety systems are compliant and effective.

What are the key differences between PCQI 1.2 and PCQI 2.0?

The main changes reflect the FDA’s current thinking on food safety and include:

-

Updated Hazard Analysis:

A revised hazard analysis chapter that integrates the FDA’s new guidance, including Appendix 1, to provide a more thorough process for identifying potential hazards.

-

HACCP Integration:

The course content has been restructured to integrate HACCP principles with preventive controls more effectively.

-

Refreshed Allergen Guidance:

The allergen chapter has been updated to include sesame, which was recently added as a major food allergen.

-

Improved Tools and Examples:

The course provides clearer, more modern examples and templates for developing a robust food safety plan and documenting preventive controls.

-

Streamlined Learning:

Some material was restructured to reduce redundancy and enhance clarity.

-

More Engaging Format:

The curriculum incorporates new features, such as QR codes for quick access to supporting documents and knowledge checks at the end of each chapter.

Is it mandatory to take PCQI 2.0 if I am already PCQI certified?

The FDA does not require individuals with existing PCQI certificates to retake the course. Certificates from previous versions remain valid. However, some companies or third-party auditors (such as those for GFSI schemes) may require updated training. Retaking the course is highly recommended to stay current with the latest FDA guidance and industry best practices.

How is the PCQI 2.0 course structured, and how do I pass?

Registrar Corp’s PCQI 2.0 course is delivered 100% online and self-paced, allowing you to complete the training on your schedule. The course is divided into interactive modules covering all aspects of food safety plan development, preventive controls, and FDA FSMA requirements. Each module includes instructional videos, practical exercises, and quizzes to reinforce learning.

To pass the course, you must achieve a minimum score of 80% on each module assessment. You can retake exercises as needed to ensure mastery. Upon successful completion of all modules, you’ll receive the official FSPCA PCQI 2.0 certificate, recognized by the FDA, which qualifies you to develop and implement food safety plans for your facility.

Do I need to print out the FSPCA Participant Manual and Exercise Workbook?

No, you don’t need to print the FSPCA exercise manual. All exercises are fully online and integrated into the course, so you can complete and review them digitally.

How long does it take to complete the PCQI 2.0 course and how long do I have to complete it?

Most participants complete Registrar Corp’s PCQI 2.0 course in about 22 hours, though the self-paced format allows you to move faster or slower depending on your schedule. Your progress is saved automatically as you go.

You’ll have full access to the course for one year, giving you plenty of time to review materials and complete all modules.

How do I receive my FSPCA PCQI certificate, and does it expire?

After successfully completing the course, you’ll receive an official FSPCA PCQI 2.0 certificate, recognized by the FDA as proof of your PCQI 2.0 training. Your certificate is downloadable immediately upon completion and does not expire under current FDA rules.

While retraining isn’t required, refresher training every few years is recommended to stay up to date with the latest FDA and FSPCA updates.

How do I update my LinkedIn profile?

Once you complete your Registrar Corp PCQI 2.0 course and receive your certificate, you can easily add it to your LinkedIn profile:

- Log in to your Registrar Corp account and download your digital certificate.

- Open LinkedIn and go to your Profile.

- Scroll to the Licenses & Certifications section and click + to add a new credential.

- Enter the certificate details:

- Name: e.g., “FSPCA PCQI 2.0 Certification”

- Issuing Organization: Registrar Corp

- Credential ID: (optional – copy from your certificate)

- Credential URL: (optional – link directly to your digital certificate)

- Click Save, and your certification will now appear on your LinkedIn profile.

What other courses do you recommend?

To compliment your PCQI certification and continue to advance your skillsets, we recommend the following Registrar Corp online courses:

HACCP Certification

Strengthen your foundation in hazard analysis and critical control points, which is essential for effective preventive controls and food safety plan development.

FSVP Training

For importers, understanding Foreign Supplier Verification Programs complements PCQI skills by ensuring suppliers meet the same rigorous food safety standards your facility enforces.

Better Process Control School (BPCS) Certification Courses

Gain certification in acidified, retort, or aseptic food processes to meet FDA compliance requirements and expand your expertise in specialized food processing operations.

Free Guide

Instructor

Meet Your PCQI Course Instructor

Cynthia Weber, FSPCA Lead Instructor

Dr. Cynthia Weber is a seasoned food safety expert with over 25 years of national and international experience in Food Safety Management.

As a Lead Instructor for the Food Safety Preventive Controls Alliance (FSPCA) courses on both human and animal food, she also holds certifications as a Lead Auditor for GFSI schemes, including ISO 22000 and FSSC 22000. Her expertise extends to being a registered SQF Trainer and Consultant, as well as an Approved Trainer for BRCGS. She has also contributed to the development of training materials and compliance tools used globally in the food industry.

Known for her clear, engaging teaching style, Dr. Weber has trained thousands of professionals worldwide, helping them develop and implement compliant food safety plans under the Food Safety Modernization Act (FSMA). Her courses are recognized for their practical, hands-on approach, empowering participants to confidently manage food safety systems and navigate regulatory requirements.

Backed by the Registrar Corp Food Safety Team

Registrar Corp’s regulatory experts review every module for accuracy and relevance, ensuring your training reflects the latest FDA guidance and industry best practices.

Reviews

Registrar Corp’s customer reviews are independently verified by Trustpilot, ensuring every rating and comment comes from a real client experience.

The training was well-structured and provided a thorough understanding of preventive controls under FDA 21 CFR Part 117. The course content successfully connected regulatory requirements with practical application, which is essential for implementing a compliant food safety system in a manufacturing and distribution environment.

good platform to use. easy to follow

Good information