In a complex regulatory environment where protecting proprietary manufacturing processes is critical, Device Master Files (MAFs) serve as a vital tool for both manufacturers and their suppliers. MAFs allow companies to submit confidential information to the U.S. Food and Drug Administration (FDA) without exposing it to third parties. They also streamline regulatory submissions, reduce duplication, and create a framework for stronger partnerships between component suppliers and device sponsors.

This article explores the function, structure, benefits, and strategic applications of MAFs, offering insight into how companies can use them to gain competitive advantage while meeting FDA expectations.

What Is a Device Master File & Why It Matters

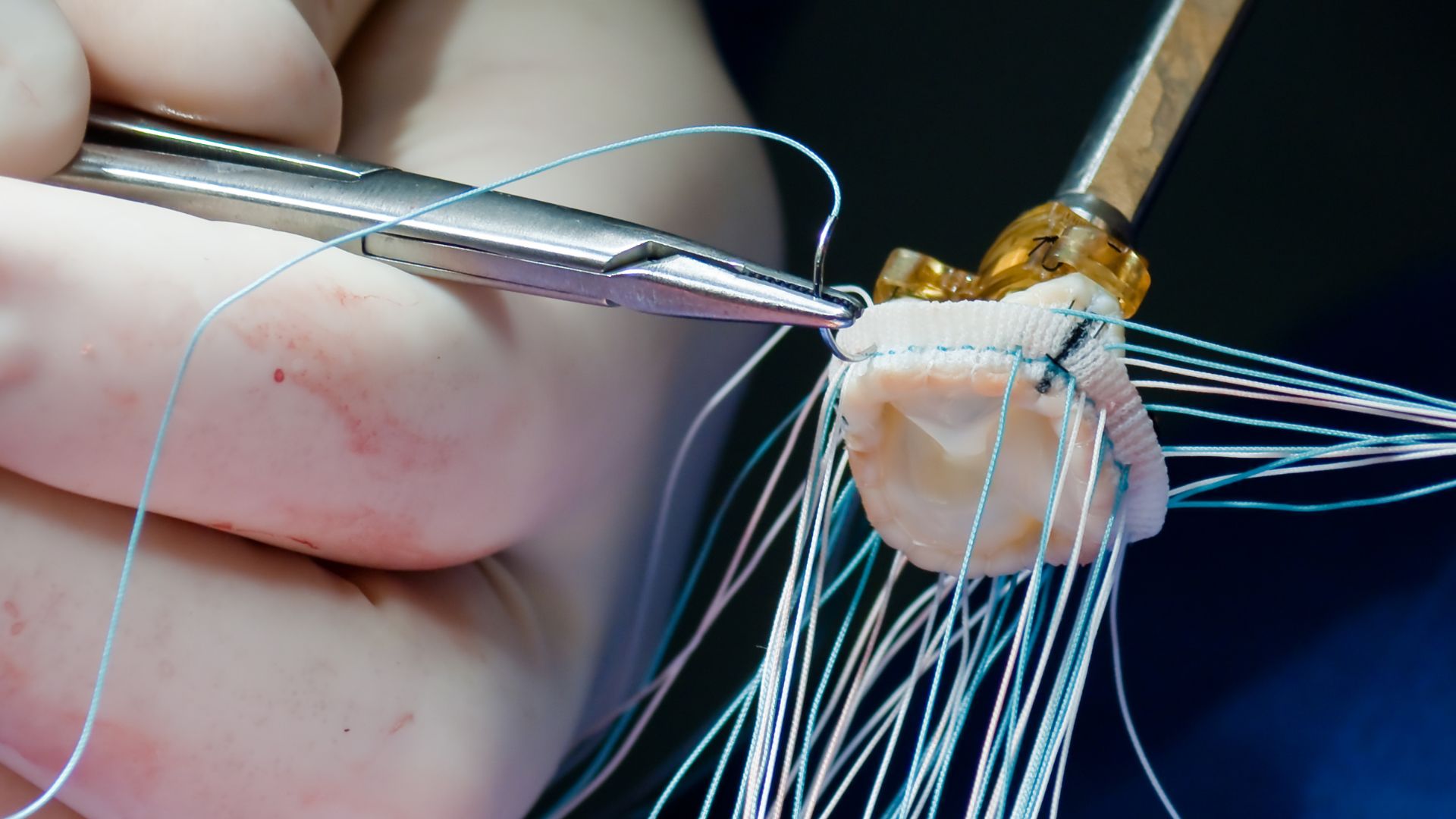

Many device manufacturers rely on component suppliers or contract manufacturers to deliver specialized parts or materials. However, when those components involve proprietary processes or confidential data, sharing the information for regulatory purposes becomes a challenge. This is where the Device Master File (MAF) plays a central role.

A Device Master File is a voluntary submission to the FDA that contains trade secret or confidential information about:

- Materials

- Manufacturing processes

- Facilities

- Testing protocols

- Clinical data (where relevant)

It allows the FDA to review critical but proprietary data without forcing disclosure to third parties, such as the device sponsor. MAFs are distinct from Device Master Records (DMRs) or Design History Files (DHFs); while DMRs and DHFs focus on internal design and manufacturing controls, MAFs are structured for regulatory reference.

When Is an MAF Useful in the FDA Review Process?

MAFs are not evaluated on their own. Instead, they are referenced in formal submissions such as:

- Premarket Approval Applications (PMAs)

- Investigational Device Exemptions (IDEs)

- Premarket Notifications (510k)

- De Novo applications

For example, if a device manufacturer incorporates a textile component produced with a proprietary chemical treatment, the textile supplier can submit an MAF to the FDA. The device sponsor then submits a Letter of Authorization (LOA), permitting the FDA to access the MAF without viewing the confidential contents themselves.

This protects intellectual property while ensuring that the FDA can conduct a complete safety and quality review.

Key Components of an Effective Device Master File

A strong MAF is one that provides sufficient technical information to satisfy FDA reviewers without revealing sensitive data to other parties. Core elements often include:

- Manufacturing process flowcharts and descriptions

- Material specifications and sourcing details

- Validation protocols and testing data

- Quality assurance and risk mitigation controls

- Preliminary biocompatibility testing

- Packaging, sterilization compatibility, or stability data, when applicable

The MAF should be organized with a clear table of contents, allowing authorized FDA reviewers to navigate its contents efficiently. This also assists the device sponsor in referencing only relevant sections without needing access to the file itself.

Benefits for Contract Manufacturers and Their Clients

While voluntary, MAFs offer considerable strategic value:

- IP Protection: Enables disclosure of critical information to regulators without sharing it with partners or customers.

- Regulatory Streamlining: Avoids duplication of documentation across multiple submissions.

- Commercial Advantage: Positions the supplier as a high-value, FDA-aligned partner.

- Reusability: A well-structured MAF can be referenced across numerous device applications.

- Quality Demonstration: Highlights the manufacturer’s commitment to quality systems and regulatory alignment.

Regulatory Submission Mechanics and Best Practices

Filing an MAF does not involve user fees, but it must conform to FDA expectations for format, organization, and content. Best practices include:

- Submit electronically using structured formats (e.g., PDF, indexed by section)

- Include a well-organized table of contents

- Use a modular design that facilitates updates and future expansions

- Coordinate with your clients to understand their intended use and align content accordingly

- Keep the file current: Amendments can be filed at any time to reflect process updates or testing improvements

Each client referencing your MAF must submit a current LOA with their own submission.

Common Mistakes and Limitations of MAFs

Despite their utility, MAFs are not a regulatory silver bullet. Key limitations include:

- No Transfer of Responsibility: The device sponsor remains fully accountable for the safety and efficacy of the final product.

- Limited Application Context: A material safe for one use (e.g., bandages) may not be safe for another (e.g., implants).

- Potential for Misalignment: Testing in the MAF may not align with the sponsor’s sterilization methods or use case.

- Outdated Files: Without active maintenance, an MAF can become obsolete, leading to regulatory delays.

It is also important to clarify that FDA access to the MAF does not guarantee approval—it simply informs their review.

Strategic Tips for Maximizing the Value of Your MAF

To make an MAF not only compliant but commercially effective:

- Align testing and content with your customers’ regulatory needs

- Consult a regulatory expert to structure the MAF in a way that protects IP while satisfying FDA standards

- Use modular, clearly labeled sections for easy reference

- Establish a regular review cycle to update the file as processes evolve

- Market the existence of your MAF as a sign of quality and regulatory maturity

Registrar Corp’s MAF Support Services

Registrar Corp helps medical device component suppliers and manufacturers submit and maintain effective Device Master Files. Our services include:

- MAF strategy and consultation

- Technical document preparation and formatting

- Submission to the FDA with structured, compliant formatting

- Letter of Authorization coordination

- Ongoing updates and amendment support

Whether you’re preparing a new MAF or updating an existing one, our team ensures your documentation aligns with FDA expectations while safeguarding your proprietary information.

Regulatory Assurance, Competitive Advantage

In an industry where both compliance and confidentiality are critical, the Device Master File offers a smart, secure solution. By enabling FDA reviewers to assess proprietary information without disclosure, MAFs support stronger partnerships, faster approvals, and safer devices.

Whether you’re a component supplier or device sponsor, leveraging the strategic power of MAFs can give you a regulatory and competitive edge.

Learn how our MAF services can help you protect your innovation while accelerating market access.